|

Woollen Carded

Semi-Worsted

Worsted (Combed)

|

Wool

Polyamide (Unbranded and Branded)

Polyester

Blends (for extra twist lock and strength/elongation)

|

NZ shears/fleece

UK Crossbred

EU Origin

Middle Eastern Wools

|

|

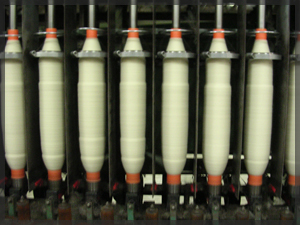

Woollen [From 1.5 to 7.0 Nm]

Semi-worsted [From 6.0 to 18.0 Nm]

Worsted [From -6 to 30 Nm]

|

Single, Plied

Velour & Frieze/Hard Twist

Fancy Twists

|

Raw White on Hanks or Cones (Dry-Spun Yarns with self-emulsifiable synthetic wool batching oil/ anti-stat lubricants)

|

|

Woollen: 1 Million Kgs/Annum

Semi-Worsted/ Worsted: 0.5 Million Kgs/Annum

|

Carpet Industry

Tufting

Axminster

Double-face Weaving

Wire Wilton

Hand tufting

Upholstery

Knitting

|

On Hanks

Weights: 0.5 – 4 kg

Circumference: 1.6 – 2.15 m

Cross Wound or Cop Built

On Cones

6” - 5°57 9°15

10” - 2°20 3°30 4°20 Cylindrical

|

|

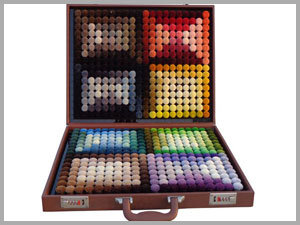

Fiber Dyeing - Dyeing, Bleaching & Washing of all Natural and Man-Made fibers

Top Dyeing - Dyeing, Bleaching & Washing of all Natural and Man-Made fibers

Blended Yarns - solid, melange and multi melange shades in worsted, semi worsted and woollen system.

YARN PACKAGE DYEING – Wool, Silk, Cotton, Linen, Polyester, Nylon, Acrylic, Viscose, Tencel and blends.

HANK Dyeing – 100 % Wool & Wool / Nylon Blends Natural & Man-made fibre yarns.

|